Core making technology and bulk material processing

With an impressive experience of more than 30 years in foundry and processing technology, KLANN Anlagentechnik from Schwerte near Dortmund has established itself as a renowned engineering office. Our comprehensive services cover all phases, starting with detailed planning through to the reliable supply of spare parts. We not only offer the design and delivery of state-of-the-art machines and systems, but also a comprehensive service that includes assembly, repair and regular maintenance.

Our diverse product portfolio includes individual units as well as the complete planning and delivery of extensive systems. These include, for example, complete core factories and highly developed processing plants that are specifically tailored to the needs of the recycling industry. Trust in KLANN Anlagentechnik to receive innovative and efficient solutions for your demanding requirements in the area of foundry and processing technology.

Nuclear making equipment

In addition to core shooting machines for foundries, KLANN Anlagentechnik offers complete turnkey core making facilities, which include the entire process from the delivery of the raw materials to the storage of the finished cores.

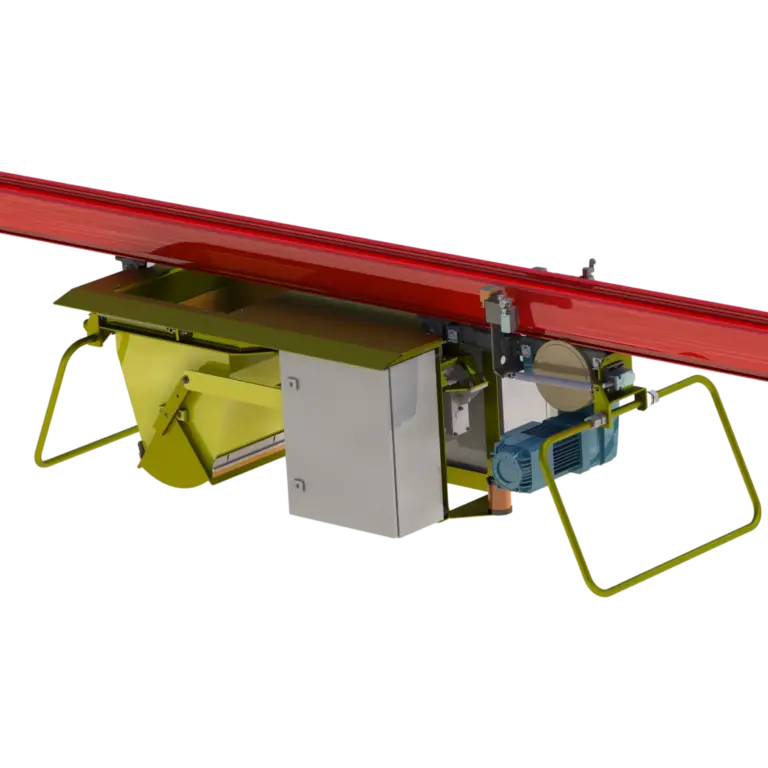

Bulk material conveying technology

KLANN offers a wide range of system technology for the processing of bulk materials, such as shredding, sifting, sorting, storage and transport. These systems are used not only in foundries, but also in the raw materials and ore industries.

The right technology for every requirement Klann systems technology

Discover our state-of-the-art foundry core making equipment that offers a variety of benefits:

Our core shooting machines are characterized by a small installation area, which enables optimal use of space. The automatic belt machines impress with their short cycle times and are ideal for efficient series production. Our easily accessible core sand mixers make cleaning and maintenance much easier.

Innovative core sand distribution systems do not require complex stage constructions and enable smooth distribution. Our binder dosing systems are easy to use and ensure precise application.

In addition, our solutions adapt flexibly to customer-specific requirements. We offer bespoke customization to ensure core making equipment is optimally suited to the needs of your foundry.

Choose KLANN Anlagentechnik and benefit from advanced technologies that make your production processes more efficient and customer-oriented.

Our Service

Maintenance and repair

For all common core shooting machines and processing systems

spare parts service

For KLANN, MAP, Vogel & Schemmann and Röper systems