Binder storage technology

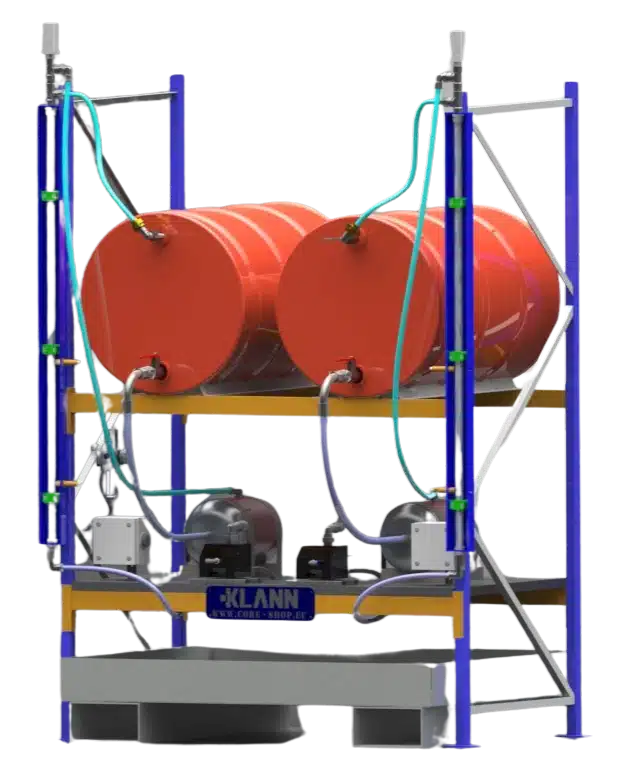

Barrel or container storage with intermediate containers and gravity emptying or pumping stations for conveying the binder over longer distances are available for binder storage. The binder storage can be provided with a cooling or heating device if the ambient temperatures fluctuate significantly. All KLANN binder storage systems are equipped with a collection tray according to WHG, quick coupling for quick container changes and adapted filter/adsorber systems to limit air contact

Container storage facilities are ideal for larger binder consumption in core machining plants.

Properties and advantages of container storage binders:

- Optical and electrical level monitoring for integration into the control system

- Buffer container for changing containers without stopping production

- Temperature control of the binders to the optimal dosing and mixing temperature

- Optional use of binder pumps when installed at a greater distance from core sand processing

- Integrated collecting tray in accordance with the Water Resources Act

- Collect dripping spills when changing containers in small sand-filled collection containers

- Easy container changes thanks to quick couplings

- Required execution even with corrosive binders

- Use of filter absorbers to avoid contact with moist air

In smaller core makers, the binders are often delivered in barrels, which then have to be stored accordingly and the binder must be continuously fed into the process.

Properties and advantages of barrel storage binders:

- Optical and electrical level monitoring for integration into the control system

- Buffer container for changing barrels without stopping production

- Temperature control of the binders to the optimal dosing and mixing temperature

- Optional use of binder pumps when installed at a greater distance from core sand processing

- Integrated collecting tray in accordance with the Water Resources Act

- Collecting drippings when changing barrels in small, completely filled collection containers

- Easy barrel changes thanks to quick couplings

- Required execution even with corrosive binders

- Use of filter absorbers to avoid contact with moist air