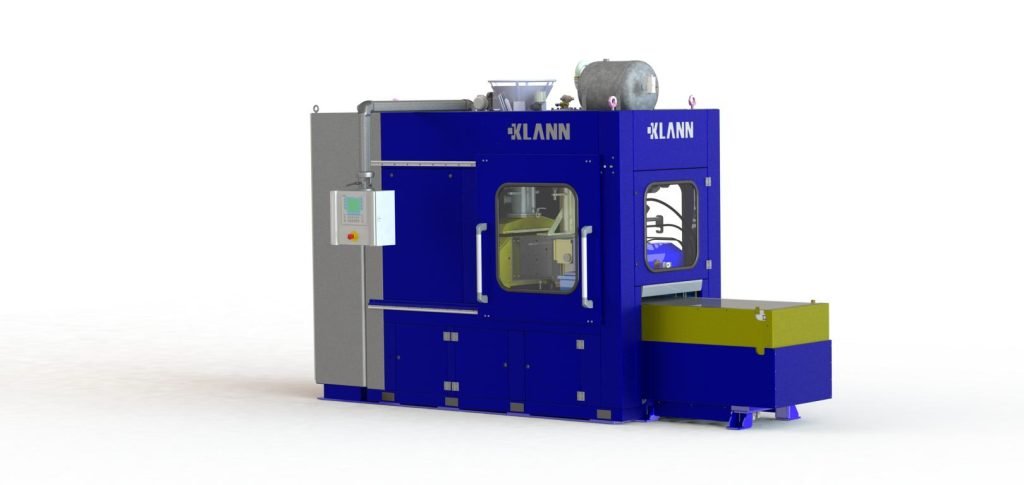

Core shooters with belt discharge, so-called core belters

are one of the most productive core making machines.

They are primarily used for the series production of cores in the automotive and fittings industries.

Short travel distances, thus short machine cycle times of up to 5 seconds

Fully automatic operation, without operator approval

Storage, discharge and buffering of the produced cores on a conveyor belt, no constant need for personnel

High core box clamping forces, precise core box guidance therefore low burr formation and correspondingly low rework on the cores

Gentle discharge and placement of the kernels on the height-adjustable conveyor belt

Complete enclosure with wide access doors for waste heat and exhaust air extraction and as protection against escaping sand

Easy core box change with optionally installed lifting equipment

Hydraulic control with proportional valve technology to reduce core breakage by gently opening the core boxes

By varying the filling volume in the shooting cylinder, repeated whirling and thus hardening of the core sand is avoided

Compact design with small installation space

Core box changing device

Mandrel pulling device

Lateral loose part pulling device

Core box changing tool

Automatic tilting head adjustment

Adaptation to different core box widths

Automatic deburring device

Base frame with cleaning drawers

Core removal robot for further processing or storage

| Unit | P5- BA/HB | P8- BA/HB | P15- BA/HB | |

|---|---|---|---|---|

| Shooting Volume | dm³ | 5 | 8 | 15 |

| Sand Supply - Feeding | dm³ | 60 | 60 | 120 |

| Shooting Pressure, adjustable | bar | 1 - 6 | 1 - 6 | 1 - 6 |

| Compressed Air Consumption per Cycle | dm³ | 25 | 32 | 50 |

| Cycle Times, without Heating, Core Pulling Device, Blowing | sec. | 5 | 7 | 10 |

| Core Box Dimensions | ||||

| min. Width/Half | mm | 40 | 40 | 40 |

| max. Width/Half | mm | 110 | 110 | 110 |

| max. Length | mm | 500 | 600 | 800 |

| max. Height | mm | 250 | 300 | 500 |

| Stroke of Clamping Device | mm | 320 | 320 | 400 |

| Width of Discharge Belt | mm | 500 | 600 | 800 |