The fully automatic core handling and the subsequent further processing of cores not only place high demands on the precision of the handling systems, but also require optimally coordinated peripherals. This is crucial to ensure a consistently high repetition accuracy and efficiency in the production process. In addition to the exact positioning of the cores, other factors, such as the integration of sensor systems for monitoring and control, play an important role.

KLANN offers specialized, fully automatic handling systems that are based on many years of experience and have proven themselves in numerous applications. These systems are able to make the entire handling and further processing process smooth and to significantly increase productivity in the core making through their high reliability. The precise alignment and positioning of the cores ensures a consistently high quality of the end products, which is of great importance in highly automated production environments.

In order to meet the individual needs and specific requirements of the customers, KLANN offers these handling systems as modularly expandable additional systems that can be seamlessly integrated into existing core-making equipment. This makes it possible to efficiently modernize and expand existing plants without interrupting ongoing operations. KLANN’s additional systems not only contribute to the optimization of core handling and further processing, but also increase the flexibility and competitiveness of the entire production.

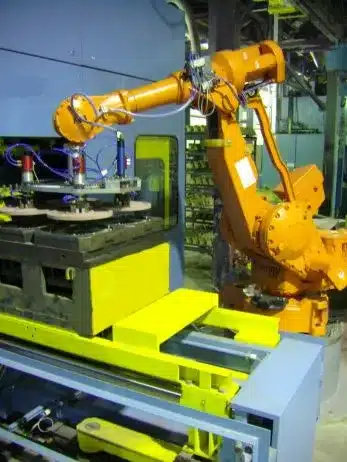

State-of-the-art robot systems with specially developed multifunction grippers can be used for the precise removal of cores from core-shooting machines and their subsequent further processing. These grippers are designed to safely handle cores of different shapes and sizes. They efficiently remove the cores from the machine and position them for further processing steps without causing damage.

The automation by these robot systems not only increases the accuracy and speed in the production process, but also reduces the need for manual intervention. This leads to higher efficiency and lower error rates. In addition, the multifunctional grippers are versatile, as they can be adapted to different production requirements, which makes the entire process more flexible and cost-effective.

For the fully automated coating of cores, specially developed sizing tanks are used, which have advanced functions such as continuous level monitoring, constant coating and automatic post-dosing. These tanks are designed to make the coating process efficient and even, so that the cores are optimally covered with the coating.

The automatic post-dosing ensures that the right amount of primer is always available to avoid interruptions in the process. Thanks to these functions, a high process stability is achieved, which ensures a consistently high quality of the coating. In addition, the automation minimizes manual interventions and thus ensures optimized and economical production.